CLEANPOWER 2025 | May 19-22 | Phoenix, AZ

Gulf Wind Technology is heading to Phoenix, AZ May 19 – 22 to exhibit at the clean energy industry’s premier

At Gulf Wind Technology, we adhere to the highest standards of best practice and process excellence specifically tailored to the technical domain of wind turbine rotors. As an entirely independent entity, we act solely in the interests of our clients, offering comprehensive, data-driven solutions that span the entire spectrum of customer value drivers, with a process that reliably delivers quantifiable benefits.

Unrelenting Excellence: We are steadfast in our commitment to excellence in everything we do, underpinned by the principles of Lean Six Sigma for continuous improvement and efficiency.

Process Rigor: We adhere strictly to best practices, delivering reliable, high-quality outcomes through disciplined process management and data driven process.

Customer Value Focus: We are driven by creating value for our customers according to their own criteria, with a strong emphasis on quality.

Safety and Compliance: Rigorous and methodical best practice in safety is applied universally and without compromise.

Breadth of Capability: We bring a unique combination of team, knowledge, and state-of-the-art equipment to every challenge, supported by a multidisciplinary approach that spans the entire rotor lifecycle and value stream.

Depth of Specialization: Our team is comprised of specialist engineers with expertise across all technical design and engineering elements of turbine blades, enabling us to address the broadest range of problem statements effectively.

Equipment and Technology: We have an unparalleled suite of tools, equipment, facilities that leverage our proprietary blade engineering technology.

Process Driven: Our rigorous processes and quality systems set new industry standards for reliability and results.

Customer Satisfaction: This is the key measure of our success.

Process Excellence: We maintain the highest standards of operational excellence in every project and strive for continuous improvement in every area.

Safety: Safety is paramount in all our operations, protecting our people, our clients, and the environment.

Gulf Wind Technology delivers an unparalleled range of solutions and services in rotor technology, from design and testing to deployment and repair. Our capabilities extend across all aspects of the rotor value chain, ensuring comprehensive support for our clients.

By partnering with Gulf Wind Technology, you gain access to a team committed to excellence, innovation, and best practices. We possess the in-house capability to resolve the broadest challenges in rotor technology, applying proprietary technology, extensive expertise, and comprehensive resources to deliver superior performance, reliability, and value to our customers.

At GWT, everything we undertake is guided by unwavering principles of excellence and the rigor of the GWT Process. This steadfast commitment covers all aspects of our operations, from technology development and internal processes to project execution and client solutions. We uphold best practices as our baseline and strive to exceed industry standards, setting new benchmarks of excellence with every solution we deliver.

As America’s only independent wind turbine rotor technology solution provider, we maintain an uncompromising stance on integrity and transparency. GWT combines engineering with deep technical insight into specific turbines, focusing solely on the needs of the customer and delivering projects as effectively as possible, independent of any manufacturer.

Safety is an intrinsic part of our culture and best practice is the only practice at GWT. All operational and technical staff are Global Wind Organization (GWO) Certified and there is compliance with the highest safety standards. Field work is strictly controlled, monitoring adherence to all on site requirements.

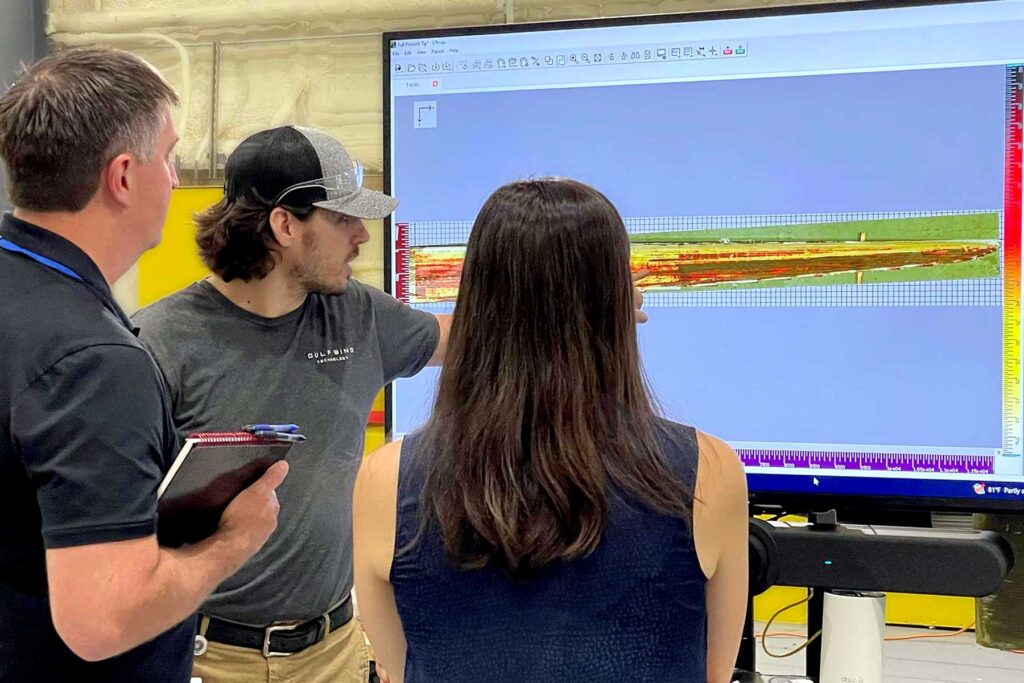

Our solutions are always data-driven through actual testing and analysis, strictly following the GWT Process framework, and benefiting from our proprietary systems and know-how. Customers receive actionable, reliable information to make well-informed choices.

We use the most advanced equipment available, and our objective is safely, reliably, and quantifiably improving the operational and financial performance of customer assets.

GWT possesses comprehensive in-house capabilities to deliver a full spectrum of engineering and technology solutions throughout the entire lifecycle of rotor blades. Our specialized engineering expertise, advanced analytical equipment, operational facilities, and extensive field services comprehensively meet the needs of operational rotor fleets. We can address and resolve problem statements in house and deliver them as end-to-end solutions.

Quality is fundamental to our culture, and key to delivering exceptional value to customers. The principles of Lean Six Sigma permeate every aspect of our working practices at GWT. We achieve high sigma variation working in the field and in our facilities, and are constantly raising our own bar.

We deliver value-driven business case analysis grounded in robust data. Customers receive clear reporting and tailored, actionable project options to move forward with. We enable decision-makers to make well-informed choices that yield quantifiable and predictable results.

We develop state-of-the-art proprietary technology to improve the reliability and performance of blades, gathering data and understanding root cause analysis to ensure solutions are as effective as possible. We continuously push the boundaries of what’s possible, innovating to implement technical solutions that significantly affect the economic performance of wind energy.

At GWT, our diverse team of specialists harnesses a wealth of knowledge and experience in rotor technology, enabling us to expertly problem-solve, assess, and validate rotor technologies. Combined with the state-of-the-art facilities at our technical headquarters, we are equipped to tackle complex challenges, deliver bespoke solutions, setting new industry standards. Our multidisciplinary approach integrates advanced analytics and best practice process, transforming challenges into actionable projects with quantifiable value outcomes.

GWT works with diverse stakeholders and interest groups to accelerate the renewable energy transition. Technical project work is ongoing with DOE, NREL and leading universities.

We lead regional educational efforts in the energy transition with participation directly in schools as well as bringing students to the Technology Accelerator.

We work with government and academia to demonstrate innovative technologies in the industry. Working directly or in consortium, we are leading development of next generation wind turbine rotor technology and solutions in the United States. Department of Energy, NREL and leading universities collaborate with us to work towards incremental and groundbreaking developments.

Gulf Wind Technology is heading to Phoenix, AZ May 19 – 22 to exhibit at the clean energy industry’s premier

In this episode of Weather Guard Lightning Tech‘s The Uptime Spotlight, our CTO, David King joins the conversation to dive

Gulf Wind Technology is heading to Nashville, TN March 3-5 to exhibit at Operations, Maintenance + Safety Conference. We hope

We’re excited to kick off a new video series on our Port Fourchon wind turbine project! This first video takes