unrivalled capability

Best Practice is Our Only Practice

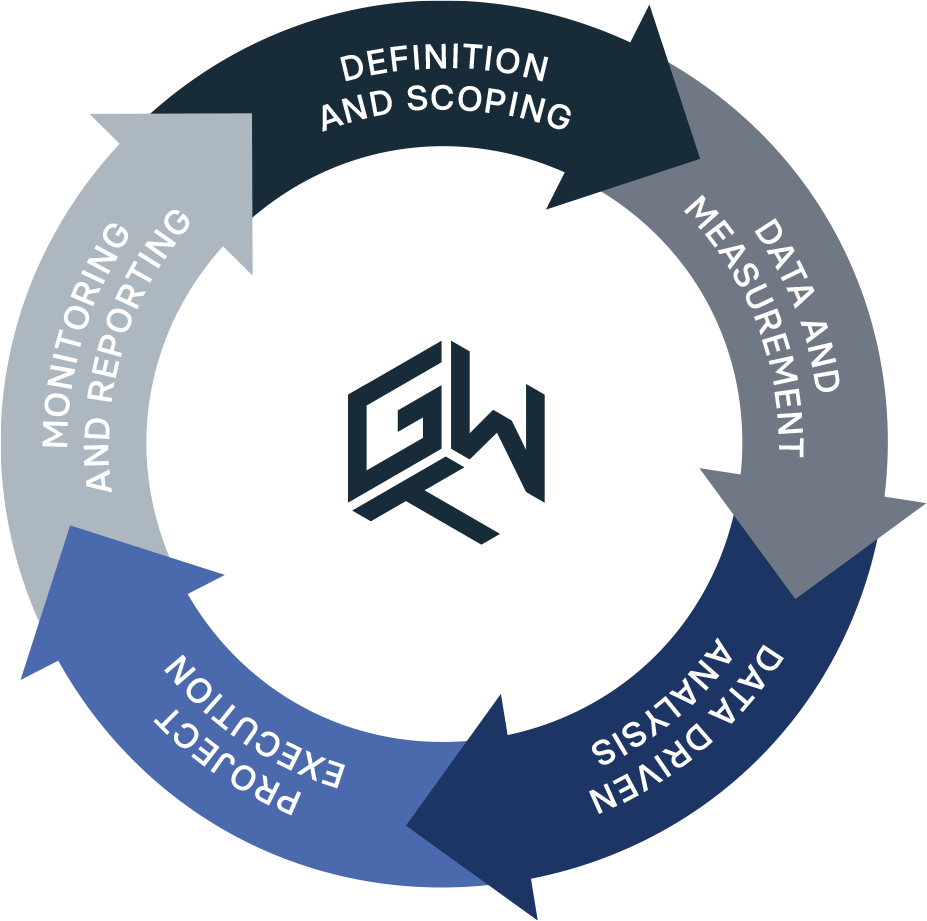

Gulf Wind Technology operates entirely within a framework of Six Sigma and lean processes. These apply both internally and externally and are intrinsic to all activities and deliverables.

Projects, analysis, and turn-key solutions are designed to meet or exceed the process and quality standards of the most sophisticated and demanding clients.