The offshore wind industry has come a long way since its inception. The journey began over 30 years ago with the installation of the first offshore wind turbine in Denmark in 1991. For much of the early years, the industry’s development was concentrated in the North Sea and the Baltic Sea, regions characterized by relatively mild environmental conditions and shallow waters. It wasn’t until the late 2010s that offshore wind started expanding into more challenging regions like the coast of China and Southeast Asia, which are prone to extreme weather conditions such as typhoons. More recently, the U.S. has begun to see wind turbines being installed off its coasts.

Moving from Ideal to Challenging Conditions

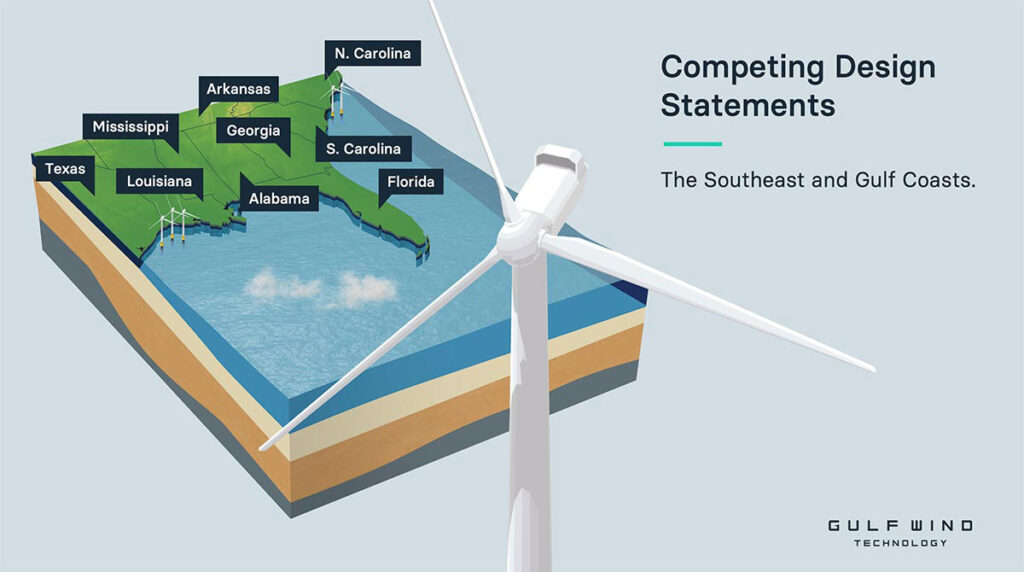

The Southeast coast of the U.S., in particular, presents unique challenges and opportunities. Despite having lower average wind speeds compared to the Northeast—typically around eight meters per second—and more frequent extreme events in the form of hurricanes, the region has begun to attract significant attention. These environmental conditions necessitate new approaches.

Wind Speed and Design Considerations

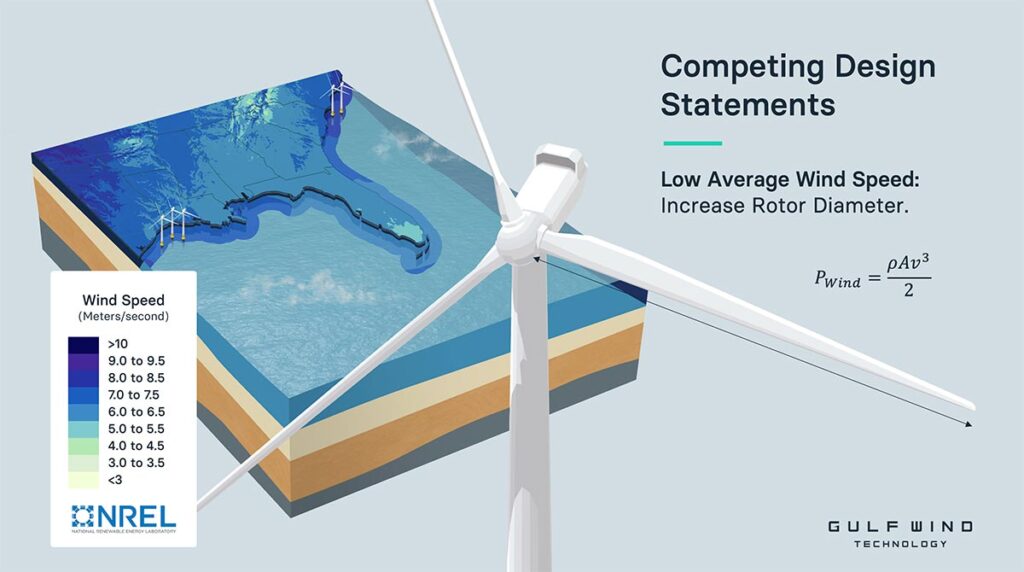

One of the primary challenges in the Southeast is the lower average wind speeds. While the Northeast coast of the U.S. enjoys hub height wind speeds well above nine meters per second, the Southeast typically sees speeds closer to eight meters per second. For engineers, this means that to capture more power from the wind, turbines in these regions need to have larger rotor diameters.

The power available to a wind turbine is proportional to the area of the rotor (the ‘A’ term in the power equation) and the cube of the wind velocity (v^3 term). With lower annual average wind speeds, turbines need to compensate by increasing the rotor size. However, this introduces another set of challenges.

Impact of Extreme Weather

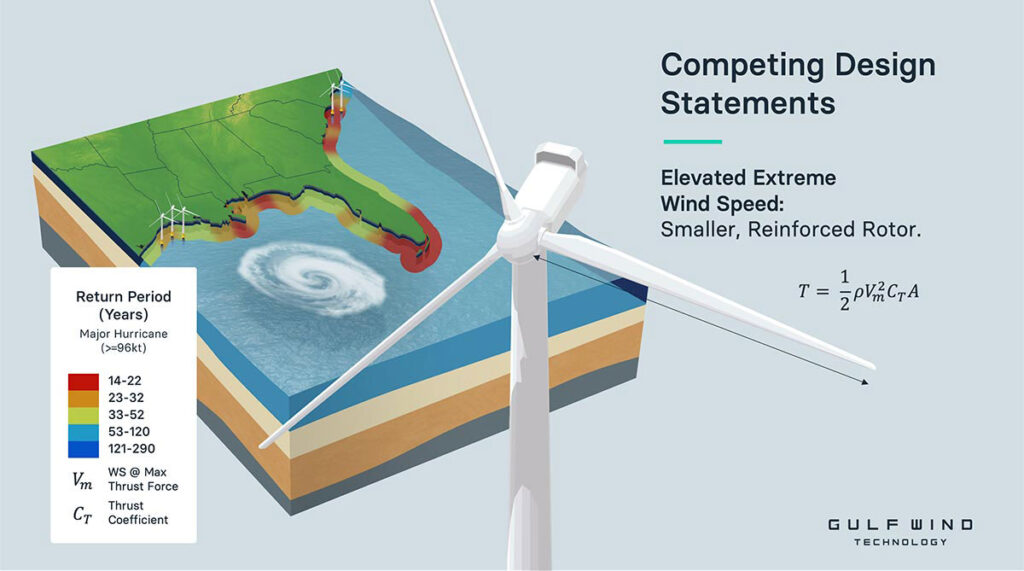

The Southeast is more prone to hurricanes compared to the Northeast. The return period for major hurricanes (Category 3, 4, or 5) in the Gulf of Mexico is typically less than 50 years. This means that over the lifespan of a wind farm (typically 20-30 years), the likelihood of encountering a major hurricane is significant, and the 50-year recurrence wind speed is likely to be elevated to reflect that risk. In contrast, the return period for such events in the Northeast is generally well above 50 years, resulting in a lower, more favorable 50-year recurrence wind speed for turbine design and siting.

During a hurricane, wind turbines are not operating, but their blades still experience significant loading from extreme winds, which in turn affects the rest of the system, especially the tower. Larger rotors mean higher thrust, increasing the loading on the turbine. This requires engineers to design turbines that are stronger, but also more expensive.

To combat these challenges, the industry has adopted strategies used in other hurricane-prone regions, such as Japan and China. These strategies include using smaller rotors and reinforcing turbine structures. For example, a four-megawatt turbine might have a 140-meter rotor diameter in a benign environment, but in a hurricane-prone area, this diameter might be reduced to about 100 meters, with additional material added for reinforcement in the blades and tower. This makes the turbine heavier, more costly, and less efficient, as the design is now driven by extreme events with low probabilities of occurring, rather than being optimized for power production at low wind speeds.

Economic Pressures

The economic pressure in the Southeast adds another layer of complexity. Power prices in this region are lower than in other parts of the U.S. and significantly lower than in Europe. To be economically viable, wind turbines in the Southeast need to be highly productive, which generally requires larger turbines with larger rotors. This creates a balancing act between designing for average wind conditions and preparing for extreme weather events.

Innovations in Simulation and Design

Advancements in simulation technology, such as large eddy simulations and other high-fidelity modeling tools, are crucial in addressing these challenges. These tools help engineers better understand the conditions that turbines will face, particularly within a hurricane boundary layer. By accurately defining these conditions, turbines can be designed to meet exact requirements without unnecessary over-engineering, which can result from poorly understood atmospheric conditions, aerodynamic phenomena, and insufficient problem statements.

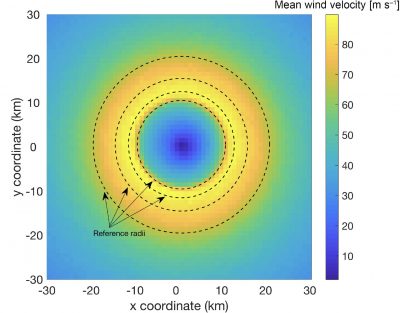

Above: Mean horizontal wind speed near the DTU turbine hub height of 119m for the entire 10 min hurricane simulation on a 1 km 1 km grid. The four dashed circles represent the reference radii of 10, 12, 15, and 20 km. (Image: Kapoor et al, 2020)

Think of it like a Swiss Army knife: it can do many things, but none of them exceptionally well. Similarly, designing a turbine without a full understanding of the inflow conditions can result in a product that is not optimal for any specific situation and not cost-effective. By leveraging advanced simulations, the industry can develop solutions tailored to the specific challenges of the Southeast, balancing durability, efficiency, and cost.

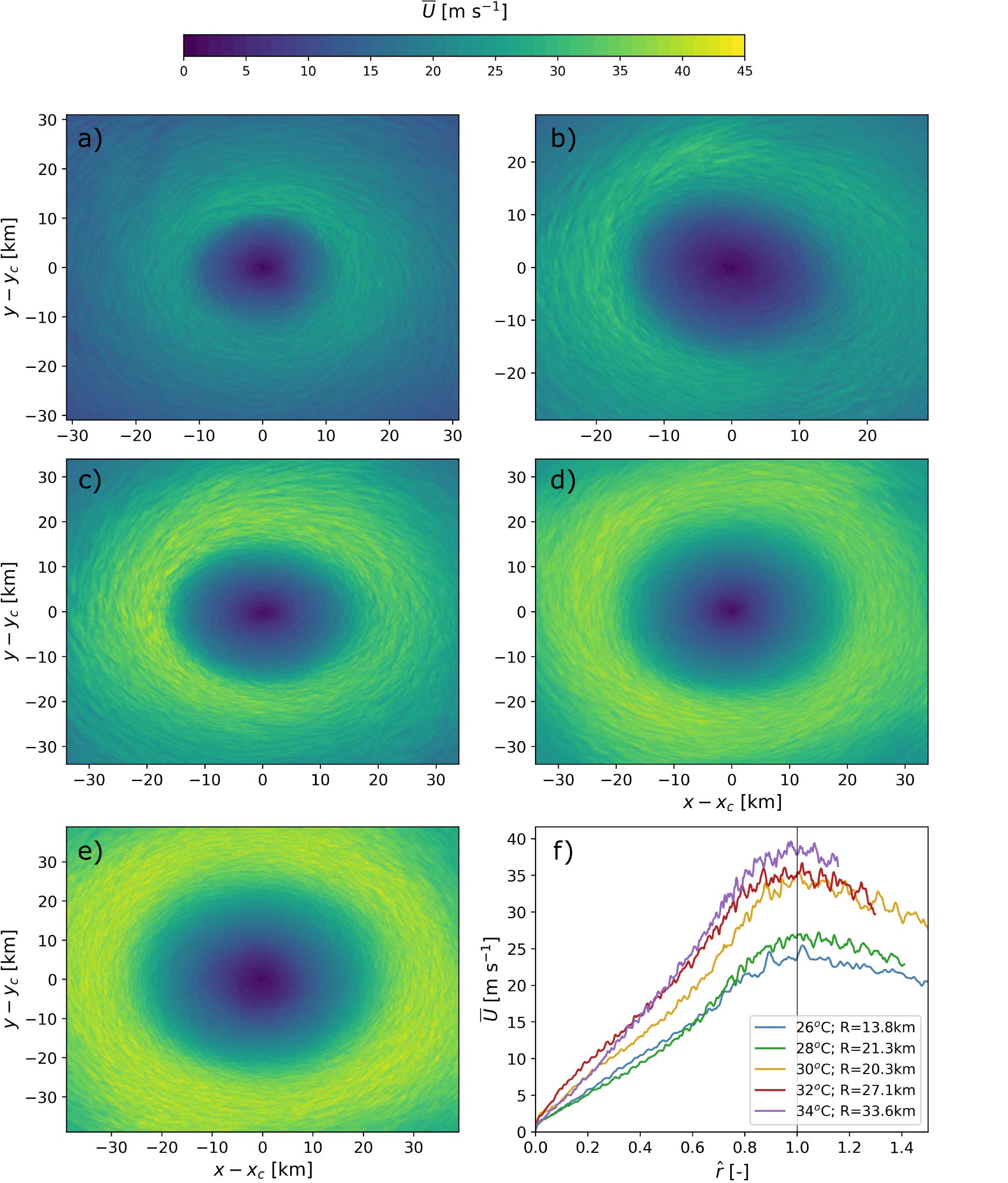

Above: Time-averaged horizontal wind speed at 10m above the surface for the a) 26 ◦C, b) 28 ◦C, c) 30 ◦C, d) 32 ◦C, and e) 34 ◦C tropical cyclone simulations. Panel (f) shows the radial distribution of horizontal wind speed for all tropical cyclones. The x−axis in panel (f) represents the normalized radial location ˆr = r/R. The velocity fields are averaged over the 50- or 60-min simulation time period. (Image: Sanchez Gomez et al, 2023)

The Path Forward

Through ongoing collaborations among national labs, universities, and industry experts, there is confidence in the sector’s ability to innovate and overcome these challenges. Gulf Wind Technology is developing, testing, and implementing the first suite of optimized technical solutions for a Gulf of Mexico-specific wind turbine that are technically sound, robust, and economically viable.

Conclusion

As the offshore wind industry continues to mature and expand into new regions with diverse challenges, the integration of engineering innovations, economic considerations, and advanced modeling tools will be key to unlocking its full potential. This approach will not only help cater to the specific needs of regions like the Southeast U.S. coast but also enhance the overall efficiency and sustainability of offshore wind energy globally.

Gulf Wind Technology believes that through careful analysis, innovative design, and strategic collaborations, the future of offshore wind is promising and will play a pivotal role in the global transition to renewable energy.